MBR Integrated Equipment

MBR Integrated Equipment

Overview

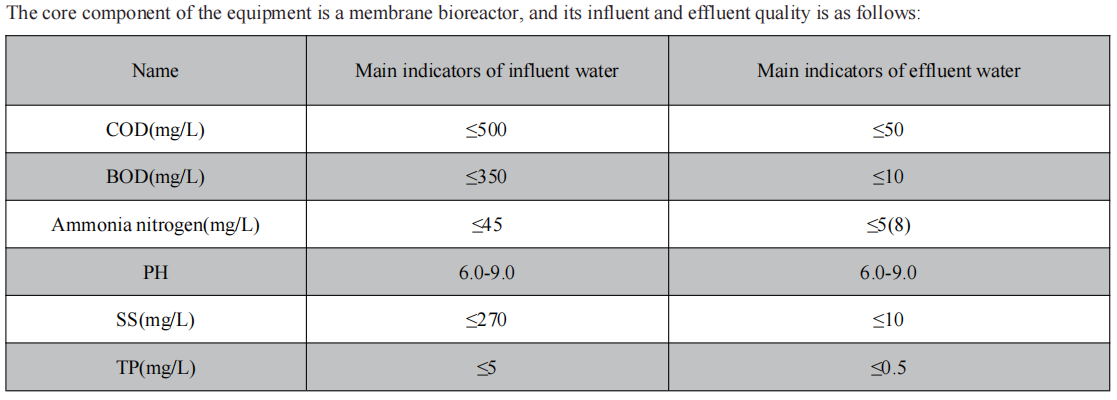

The core component of MBR integrated wastewater treatment equipment is membrane bioreactor (MBR), which is a new wastewater treatment technology combining membrane separation technology with biotechnology.

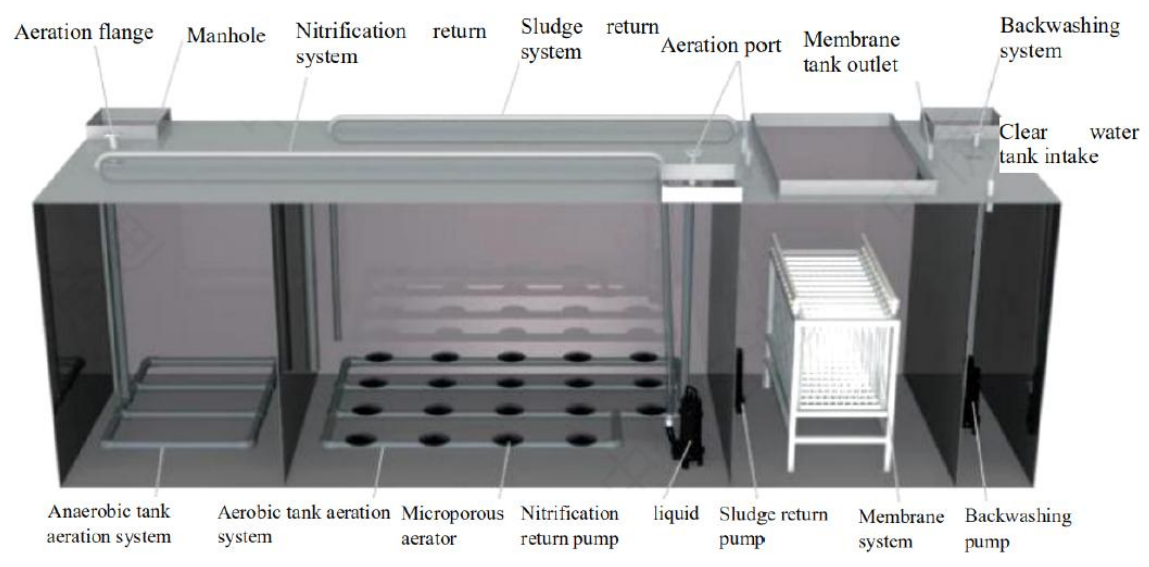

Wastewater enters MBR system. Zone A is facultative aerobic zone for placing filler and make full contact with sewage. Zone О is aerobic zone for place filler, aeration heads are installed and membrane module are placed in membrane tank, so that PVDF membrane is used to intercept the active sludge and macromolecular organic matter, and save the secondary sedimentation sink. Therefore, the concentration of activated sludge can be greatly increased, the hydraulic residence time (HRT) and sludge residence time (SRT) can be controlled separately, and the refractory material can be continuously reacted and degraded in the reactor. After further treatment, the treated water can reach the discharge standard or be reused. In addition, the air delivered to MBR system is also a very important part of the treatment process. It can promote the circulating flow of the fluid in the reactor, improve the degradation efficiency of the active sludge, and make the hollow fiber membrane filaments rub each other and clean the membrane assembly.

Advantage of Equipment

(1) Compact, small size, small floor area, geographical structure, removable, and easy to greening, without fly and mosquito breeding;

(2) The removal rate of organic pollutants is high and the effluent quality is stable;

(3) Easy operation, convenient construction, no need of special maintenance, and good self-protective equipment;

(4) The quality of the treated water is good and meets the requirement of the discharge standard;

(5) The equipment can be flexibly configured according to the quality of raw water, so that it has wide applicability;

(6) The most important part of MBR is its control principle. The suction pump is controlled by liquid level and operated intermittently. The hollow fiber curtain membrane also needs linkage control with clear water backwashing and drug washing. Our company fully grasps its control principle to maximize the service life of the membrane; Aeration flange Manhole Nitrification return system

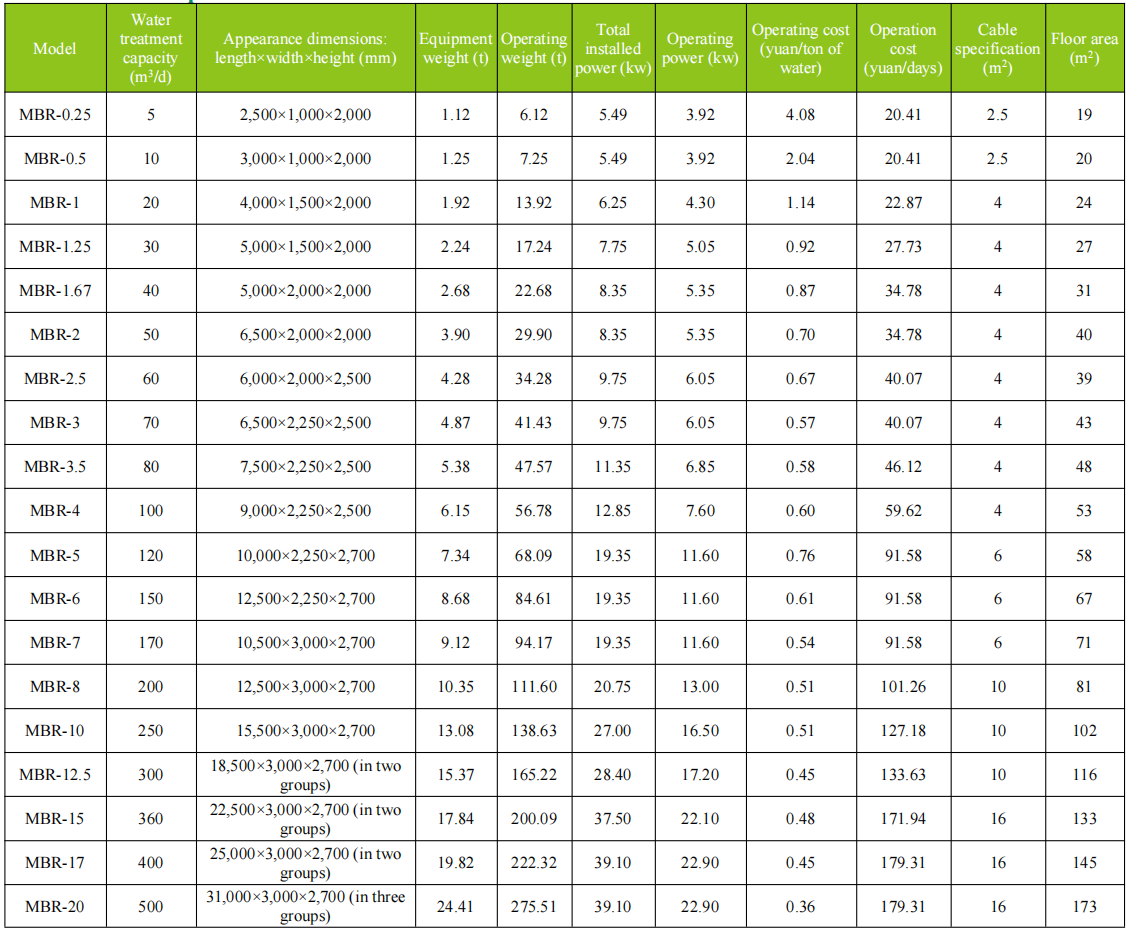

Technical parameters

Performance Parameters

Contact: Tina

Phone: 13370035529

Tel: +8613370035529

Email: tina@qileegroup.com

Add: Room 220-221, No. 2795 Longming Road, Minhang District, Shanghai

We chat